10 steps to Buying a 3D Printer in New Zealand

So you have decided to buy yourself a 3D printer after hearing about the amazing things it can build. You want to get started on printing models of your own - like a custom phone case, cosplay materials, figurines, musical instruments – the possibilities are endless. However, there are a few things you need to know before diving into the world of 3D printing. There are a lot of 3D printers on the market today that have varying specifications, which in turn cater to different demands. On top of that, there are technicalities about 3D printing that you really should look into. To help you decide on which printer to make your first, we have compiled a list of 10 things you need to know before you buy a 3D printer.

1. Types of 3D printers

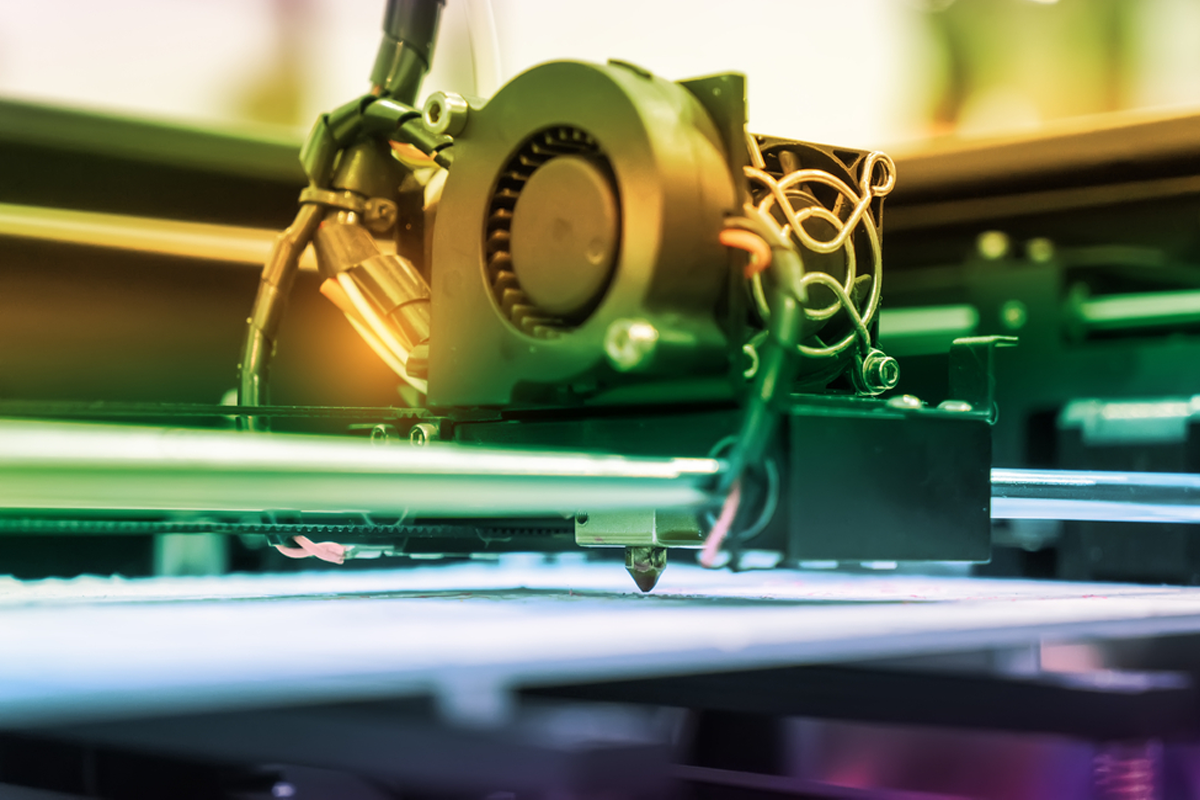

3D printing is a broad term that covers the technologies required for producing physical materials. The one you’ve probably heard of in the media and the most popular among hobbyists is the one that uses fused deposition modelling.

Fused deposition modelling (FDM)

FDM is an additive process, where a model is created by heating and extruding plastic pieced together layer-by-layer. Most of the 3D printers referred to in this post work on FDM, as they are more widely available and easy to find. There are two other types of 3D printing available stereolithography and selective laser sintering. They are much more expensive compared to FDM.

Stereolithography (STL)

STL also uses the additive process but instead of extruding plastics, the process utilises an ultraviolet light beam to harden a model from a pool of photosensitive liquid. This allows for a higher quality printout.

Selective laser sintering (SLS)

SLS is similar to stereolithography, except that the process involves lasers and powders instead of UV light beams and liquid. A laser is used to melt the powder, creating a layer of the printed material. This allows some models to print metal objects, which is not possible in the other two processes.

Direct Light Processing (DLP)

DLP is resin based system like SLA, However, the parts are build upside down in a vat of resin and the light source that solidifies the resin is a LCD screen. There are advantages and disadvantages to this process over SLA. SLA requires less support to create the parts as it does not need to keep the part stuck to the bed when it does a layer change. But the major advantage is that the DLP system can print an entire bed full of parts at the same time which can massively reduce production time.

2. Build your own or buy one

The 3D printing community is one made of creators and makers, so it makes sense that many people would like to try their hand at building a 3D printer of their own. There are building instructions and 3D printer kits available online if you decide to go down this route. Building your own printer can be cheaper than buying one but if you don’t have the time, you could always buy a pre-assembled printer. Your final decision will depend on whether you are interested in tinkering with the technology, or just want to start printing right away. Building your own can also be advantageous to learn how the 3D printer works and give you a good insight if things go wrong.

3. Price

The price of 3D printers for sale in New Zealand is changing all the time. Prices depend mainly on the quality of the output, ease of use and longevity (quality of the components used). In general, the higher-quality ones tend to go above $1000 - professional printers can even go above $5000 e.g. the Creatbot or Cubicon series. But if you are just dipping your toes in 3D printing, you can start with simple models like Creality that go for as low as $100.

4. Materials used to print

The two common materials used for 3D printing are polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Both are thermoplastics that will become soft and malleable when heated and frozen when cooled. They are sold as 1kg (2.2lbs) spools of filament, priced in the $30 range.

Acrylonitrile butadiene styrene (ABS)

ABS is a petroleum-based plastic that is a popular choice because of its strength and flexibility – think Lego bricks (which can be made using 3D printers). Its flexibility makes creating interlocking pieces easier to create and work with. It also has a higher melting point so your creations will be less likely to deform under high heat.

Disadvantage: It takes longer to cool compared to PLA and models are susceptible to warping.

Disadvantage: It emits fumes during printing (more on this below).

How to choose

You need to know which material is suitable for your final product. From there you can choose which type of printer you should buy. It is important to know that not all printers can accept both materials – some will work with only one type.

When it comes to filament size – 1.75mm or 3mm in diameter – it doesn’t factor much into the end quality. More popular printer brands go with 1.75mm so it is recommended that you start with that.

5. Playing with heat

The most important thing to remember is that you are working with heated plastics. Extruders, plastics and in some printers the print bed itself can get very hot and can cause bad burns if you are not careful. Some printers have no enclosure around the print area so you should practice extra caution with these printers. It is important to keep your 3D printer in a well-ventilated room and you should be wary of fumes. During the printing process, expect fumes to be emitted, particularly when you use ABS plastics. These fumes are reported to be rather overwhelming although there is little to no research that states the impact they have on general health. Still, it is best to take the necessary precautions, particularly if you will be using 3D printers a lot.

6. Quality

To produce high-quality 3D printed products, you need to take note of two things: print resolution and print speed.

Print resolution refers to the level of detail the printer can get, measured in microns – the smaller it is, the higher level of detail in the objects you can create. Print speed measures how fast the printer can move its extruder – the higher the print speed, the faster it will print. Note that other features may affect the print speed, such as the acceleration and deceleration of the printer, which helps prevent the printer from shaking.

7. Obtaining a 3D model

When it comes to getting a 3D model, there are two routes. You can create it yourself or download a pre-made model blueprint from the internet. If you intend to create your own model, there are a variety of software, both free and commercial, that will help you bring your creation into the real world. If you like, you can even learn 3D modelling.

8. STL files

The STL file is the standard file format that you will use to print your 3D model into a physical object. The file can be generated using most CAD programs so if you are building your own 3D models, chances are the software you are using can output one. Basically inside an STL file is the information needed to produce a 3D model. The model itself is broken down into a series of triangles and a list of their XYZ coordinates is used by the printer to create the physical object, layer-by-layer.

9. Slicing software

Once you have an STL file of the model you want to print, you will have to put them through a slicing software. What slicing does is that it “tells” your printer how to print your model. It provides instructions on the number of layers needed, the starting position of the printer and the parts of the model that should be solid or hollow. Most 3D printers come with their own software.

10. Community

The great thing about a new technology trend is that there is almost always an online community devoted to it. It is no different with 3D printers. Check online for a community of people who own a particular brand, to get more insight and answers to questions you may have about the ins and outs of that printer. If the community is small, or worse, nonexistent, the lack of users should raise a red flag about that particular brand. All you need to make a sound investment is to read up more about that brand and its competitors so you know what you are getting into.