3Design Services

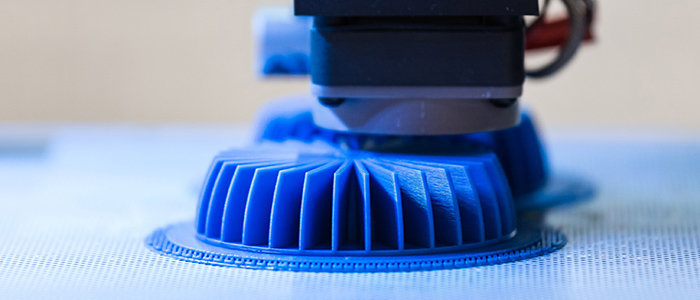

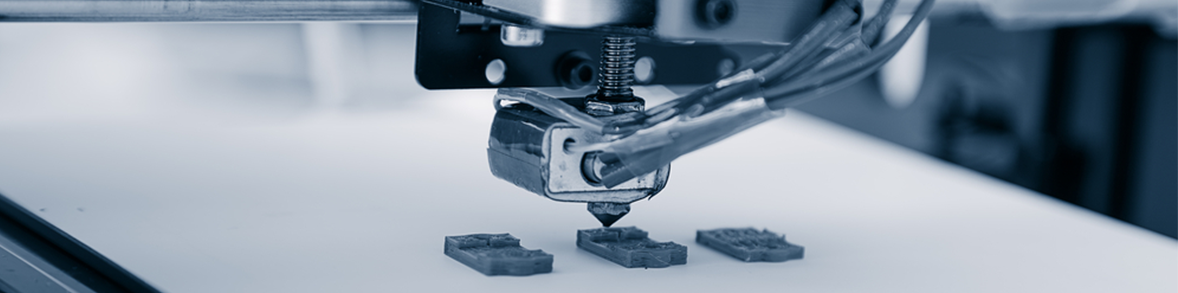

There are several different processes that come under the 3D printing umbrella, but they all work on the same basic principle of converting a 3D digital design into thin cross sections and depositing material on top of each of these cross sections to produce a 3-dimensional object. This is known as Additive Manufacture or AM.

3D printing, additive manufacturing and related technologies explore emerging challenges and opportunities ranging from new developments of processes and materials to new simulation and design tools as well as informative applications and case studies. Novel applications in new areas, such as medicine, education, bio-printing, food printing, art and architecture are also encouraged. Our team combined has over twenty years of industry experience and we bring high-quality 3D printing within everybody’s reach.

3Design has been 3D printing for over 6 years in multiple processes like FDM, SLA, DLP, SLS and more. If you require 3D printing in Auckland, Tauranga or Buff our fast efficient service can get it done.

3D Drafting

If you have a brilliant idea you want to see turned into a solid object, or you’re a hobbyist looking to find new ways of creating, 3Design can work with you to turn your ideas into a physical form. 3Design can offer you this process at the fraction of the cost of traditional drafting methods. Using our 3D printers your ideas can take shape for as little $300 dollars. 3D technology can provide alternative solutions for the home inventor and let you express your creativity.

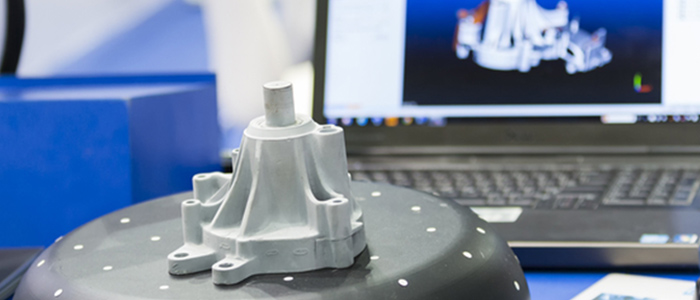

Rapid Prototyping

3Design can help with all your product manufacturing needs with our affordable on-site 3D prototyping. We have a range of in-house 3D printers waiting to bring your projects and products to life. If you are wanting to make high-quality specialised products or samples that are affordable we are happy to give you a quote. This service is a cost-effective option as it eliminates the costs for initial setup, tooling and moulding.

Read More Quick Quote3D Scanning

Using our 3D scanner, 3Design can offer you a range of solutions to familiar problems that may not have been possible in the past without innovative 3D technology. Our 3D scanner allows us to scan a variety of objects in all shapes and sizes. 3D technology can extract accurate targets from cluttered backgrounds. The scanning process is quick and in minutes your object can be enhanced, cropped and ready for 3D printing.

Read More Quick Quote3D Printer Farm

3Design has created a New Zealand first with a publicly accessible remote 3D printing farm. If you're wanting to try 3D printing but don't want a massive outlay, this is an economical way to give it a go. It’s a simple idea that could solve a complex and costly 3D challenge. The 3D printer farm is a new initiative that offers you the chance to engage with 3D printing but without the hassle of actually running a printer.

Read More Quick Quote3D House Models

Present your property in a unique way with a 3D printed house model. As the 3D printing revolution takes off, 3D printed house models are becoming more common. Builders, architects and property developers can show their clients their appreciation by gifting them a model of their new home. If you're looking for that competitive edge over your opposition, this will be a new way to make your customers smile.

Read More Quick Quote